Blog

From Factory Floors to Control Rooms: Applications of Industrial LCD Displays

Welcome to the world of industrial LCD displays! These technological marvels have become integral to a wide range of industries, transforming factory floors into control rooms filled with vibrant visuals and critical data. Whether you’re involved in manufacturing, transportation, or any other industry that requires advanced monitoring systems, industrial LCD displays are here to revolutionize your operations.

In this blog post, we’ll explore the various types of industrial LCD displays available and delve into their advantages and disadvantages. We’ll also take a closer look at some exciting applications where these displays shine brightest. So fasten your seatbelts and get ready for an enlightening journey through the fascinating universe of industrial LCD displays!

Overview

Industrial LCD displays are not your average monitors. These rugged, high-performance screens are specifically designed to withstand the demanding conditions of industrial environments. Whether it’s extreme temperatures, vibrations, or exposure to dust and moisture, these displays can handle it all.

One key feature that sets industrial LCD displays apart is their durability. They are built with robust materials and undergo rigorous testing to ensure they can withstand harsh conditions without compromising performance. This makes them ideal for use in factories, warehouses, oil rigs, and other challenging work environments where traditional monitors would quickly fail.

Another notable aspect of Industrial LCD Monitors is their versatility. They come in a variety of sizes and resolutions to suit different needs, from compact panels for tight spaces to large-scale displays for expansive control rooms. Additionally, they offer various mounting options such as wall-mounting or panel-mounting capabilities for seamless integration into existing systems.

Furthermore, industrial LCD displays boast impressive brightness levels that allow clear visibility even in brightly lit areas or outdoor settings—a crucial factor when dealing with critical data monitoring or real-time visualizations on factory floors or transportation hubs.

Moreover, these displays often incorporate advanced touch screen technology like resistive touchscreens or capacitive touchscreens which enable intuitive user interaction without the need for additional input devices like keyboards or mice.

In summary (conclusion), Industrial LCD Displays provide durable and versatile solutions tailored explicitly for demanding industries’ needs—delivering reliable performance under extreme conditions while offering excellent visibility and user-friendly interfaces

The Various Types of Industrial LCD Displays

The world of industrial LCD displays is vast and varied, offering a wide range of options to suit different applications. One type of display commonly used in industrial settings is the ruggedized LCD panel. These panels are designed to withstand harsh conditions such as extreme temperatures, dust, and vibrations.

Another type of industrial LCD display is the sunlight-readable display. As the name suggests, these displays are specifically designed to be easily readable even in bright sunlight. This makes them ideal for outdoor applications where visibility can often be a challenge.

in industrial Box PC,Touchscreen displays are also popular choices for many industrial applications. They offer intuitive user interfaces that allow operators to interact directly with the display, eliminating the need for external input devices. This not only saves space but also improves efficiency by reducing operator error.

For environments that require high levels of cleanliness and hygiene, there are also hygienic LCD displays available. These displays feature smooth surfaces that can be easily cleaned and sanitized without compromising their functionality.

In addition to these types, there are specialized LCD displays tailored for specific industries or purposes. For example, some industries may require explosion-proof displays that meet stringent safety standards in hazardous environments.

The various types of Tough Industrial Displays cater to different needs and requirements in terms of durability, readability, interactivity, cleanliness, and safety. By choosing the right type of display for each application, businesses can ensure optimal performance and productivity in their operations.

The Advantages of Industrial LCD Monitors

Industrial LCD displays offer several advantages that make them an ideal choice for various applications. One of the main benefits is their durability and resilience in harsh environments. These displays are specifically designed to withstand extreme temperatures, humidity, vibrations, and even exposure to dust and water.

Another advantage of industrial LCD displays is their high brightness and contrast ratio. This allows for clear visibility, even in brightly lit or outdoor conditions where glare can be a problem. With adjustable backlighting options available, users can easily optimize the display’s brightness based on their specific needs.

Industrial LCD Monitors also excel in terms of reliability and long-term performance. They are built with robust components that ensure continuous operation without any degradation in image quality or responsiveness over time. Additionally, many industrial LCD displays come with advanced features like wide viewing angles, fast response times, and anti-reflective coatings for enhanced usability.

Furthermore, these displays offer flexibility when it comes to connectivity options. They typically have multiple input interfaces such as HDMI, VGA, DVI-D, or DisplayPort which allow seamless integration with different devices or systems.

The Disadvantages of Industrial LCD Displays

The Disadvantages of Industrial LCD Displays

While Tough Industrial Displays offer numerous advantages, it’s important to consider the potential drawbacks associated with these devices. One disadvantage is their vulnerability to extreme temperatures, both hot and cold. Unlike ruggedized or outdoor displays that are specifically designed for harsh environments, standard industrial LCD displays may experience performance issues in temperature extremes.

Another drawback of industrial LCD displays is their susceptibility to damage from moisture and humidity. Moisture can seep into the display panel and cause malfunctions or permanent damage if not properly protected. This is particularly problematic in industries where high levels of humidity or exposure to liquids are common.

In addition, Industrial LCD Monitors typically have limited viewing angles compared to consumer-grade monitors. This means that users must be positioned directly in front of the screen for optimal visibility and clarity. In control room settings where multiple operators need to view information simultaneously, this limitation can be a challenge.

Furthermore, industrial LCD displays often require more power than their commercial counterparts due to their durability features such as enhanced shock resistance and wide operating temperature ranges. This increased power consumption may lead to higher energy costs over time.

Customization options for Tough Industrial Displays might be limited compared to consumer-grade monitors that come in various sizes and resolutions. Industries with specific display requirements may face challenges finding suitable options within the range available.

Considering these disadvantages alongside the benefits is crucial when selecting an industrial LCD display solution for your organization’s needs

Applications of Industrial LCD Displays

Industrial LCD displays have a wide range of applications across various industries. These rugged and durable screens are designed to withstand harsh environments, making them ideal for use in factory floors, control rooms, and other demanding settings.

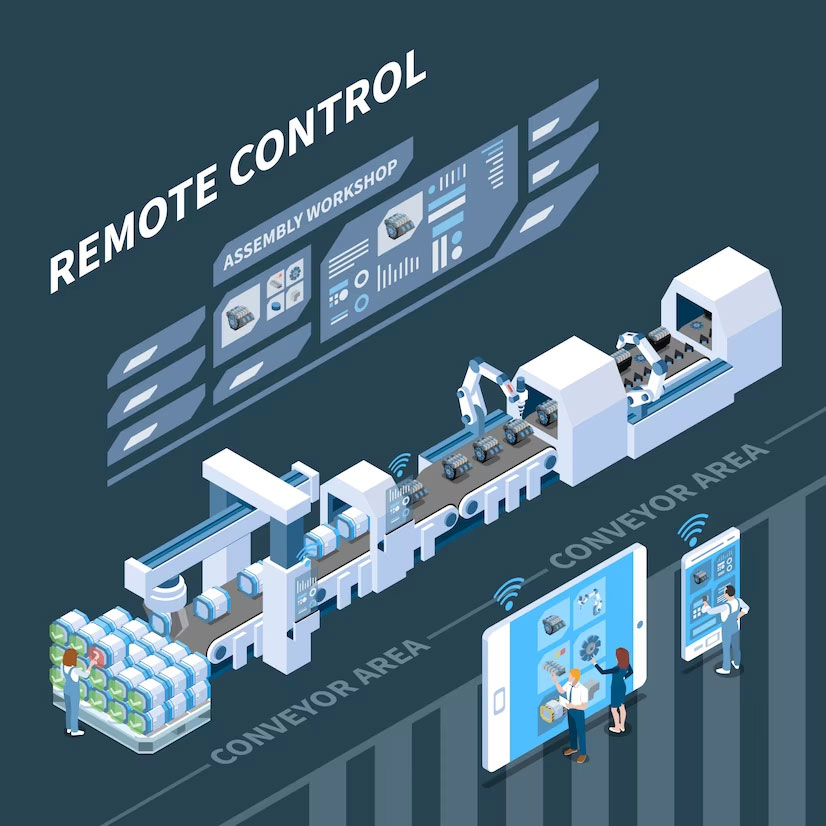

One common application of Industrial LCD Monitors is in manufacturing plants. These displays can be used to monitor and control different processes on the factory floor, providing real-time data on production rates, equipment status, and quality control measures. With their high resolution and bright screens, industrial LCD displays ensure that operators can easily view critical information at a glance.

In control rooms, industrial LCD displays play a vital role in monitoring complex systems such as power grids or transportation networks. Operators rely on these displays to provide visual feedback on the performance of various components and to quickly identify any anomalies or issues that may arise. The ability of Industrial LCD Monitors to handle large amounts of data feeds is crucial in these scenarios.

Another important application is in outdoor environments where sunlight readability is essential. Industrial LCD displays with anti-glare coatings are used in outdoor kiosks, digital signage boards, or even military operations where reliable visibility under direct sunlight is required.

Furthermore, Tough Industrial Displays find applications in healthcare facilities for medical imaging purposes such as X-rays or ultrasounds. Their high-resolution capabilities allow for accurate diagnosis while ensuring patient safety through compliance with medical standards.

The versatility of industrial LCD displays extends beyond traditional industries into emerging fields like augmented reality (AR) and virtual reality (VR). These advanced technologies heavily rely on high-quality visuals provided by robust display solutions like industrial-grade monitors.

In conclusion,

From manufacturing plants to control rooms and from healthcare facilities to AR/VR applications – it’s evident that the applications for industrial LDCDisplays are vast and diverse across multiple sectors. As technology continues advancing further into new frontiers,

the demand for reliable display solutions will only grow stronger.

Conclusion

Industrial LCD displays have revolutionized various industries by providing reliable and efficient visual solutions for a wide range of applications. These displays offer numerous advantages, including high-resolution images, durability, flexibility, and compatibility with modern technology. However, they also come with some disadvantages such as higher costs and limited viewing angles.

Despite their drawbacks, industrial LCD displays find extensive use in diverse sectors. From factory floors to control rooms, these displays are invaluable in monitoring processes and ensuring smooth operations. They can be found in manufacturing plants for real-time data visualization and analysis, in transportation systems for displaying critical information to operators or passengers, and even in healthcare settings for patient monitoring.

In the oil and gas industry,Tough Industrial Displays play a crucial role in offshore drilling platforms where they provide vital information about well conditions and safety protocols. In automotive manufacturing facilities, these displays are used on assembly lines to guide workers through complex tasks efficiently. Moreover, they are utilized in power generation plants to monitor energy production levels accurately.

The applications of industrial LCD displays extend beyond traditional industries as well. They have become an integral part of smart homes by acting as central control panels that manage various devices within the house. Additionally,

These examples represent just a fraction of the countless ways industrial LCD displays enhance productivity across multiple sectors.

In conclusion,

industrial LCD display technologies continue to evolve rapidly due to ongoing advancements in screen resolution capabilities and touchscreen functionalities. As more industries embrace digital transformation initiatives,

the demand for advanced display solutions will only grow stronger.

Whether it’s optimizing production processes or improving operational efficiency,

industrial TFT Screens will continue to play a pivotal role in shaping the future of many sectors worldwide