Blog

High-performance Fanless Industrial Box PC for Packaging Robot Application

Background:

With the booming development of the packaging market demand, the packaging robot industry has also ushered in a good period of development. Intelligent packaging equipment began to gradually replace traditional equipment to become the mainstream of the future, the development of packaging robot is one of the best. It can not only save labor cost, reduce the energy consumption cost of mechanical packaging machine, but also improve the production efficiency of packaging, palletizing and film work, improve the efficiency of enterprises. Compared with the traditional mechanical palentizing, it can be applied to a variety of film, bag, canning, bottle and other shapes of packaging products, obvious advantages. With the demand of automation in the packaging industry and the maturity of robot technology and the realization of industrial development, the application scope of robots in the packaging industry is becoming wider and wider. Packaging robots are known by more and more enterprises. In the future, more industries will be used because of their flexibility and reliability. Robots will replace many traditional devices and become an important assistant in the packaging field.

Technical requirements:

Most of the packaging work in food production plants, especially the arrangement and assembly of more complex packaging items, is basically manual operation, which is difficult to ensure the unity and stability of packaging, and may cause pollution to the packaged products. Even if some food production factories use packaging machinery, it is only used in some link of the whole packaging chain. For example, the front section packaging is mechanical packaging, while the second section packaging is manual.Therefore, improving the automation level and quality level of the whole packaging chain is a very important link for modern food production enterprises to carry out GMP specifications.

1. Precision of production

The robot arm is fixed and mounted on a solid seat, and the axis of the multi-axis robot is controlled by the servo motor and gear, which ensures that the robot can determine the station flexibly and freely within the working radius. Both robots and furniture can complete the rotation of ± 180, which only need to determine the grasp point and placement point, and the computer controls the movement track between the two points, and the positioning is very accurate.In addition, in order to simplify the mechanical structure, enterprises use 4-axis industrial robots, which reduces the cost of maintenance and later service

2. simplicity of operation

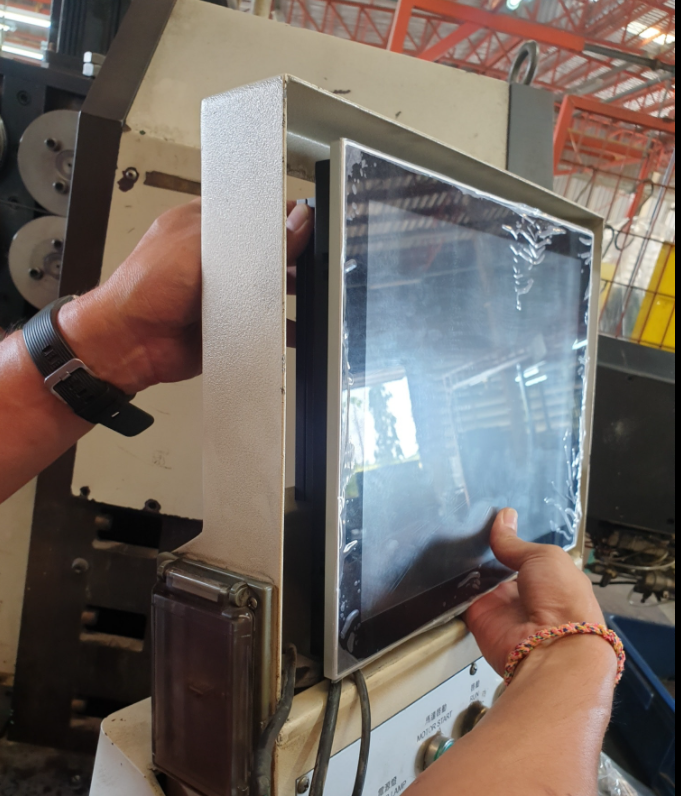

The system controls the robot, robotic claw and conveyor belt through the PLC, and the system is equipped with a special touch screen to display the information during the production process. The system adopts the advanced human-machine interface, and the operator can easily modify the parameters and do the work of the program selection on the interface.

3. Flexibility in production

The robot’s claws are mounted in the center of the flange, which can be designed as a fixed tool and can be replaced with different professional claws through automatic hand changing devices to adapt to special tasks. Multi-function claw can be suitable for the combination of work: grasp the bottle type, clamp type, grasp the carton of vacuum suction cup type, bottling and palletizing integrated claw, etc. Only according to the needs in the actual production process, the robot can replace and install different claws to meet the needs of flexible production.

TAICENN Solutions:

TACENN TBOX-2 series can offer Intel mobile processors with Baytrail Celeron, Apollo lake, 6th & 7th gen. Core i3/i5/i7 processors. The Box PC is designed with a rich vertical IOs, including 2* Intel GLAN, 6* USB3.0/2.0, 6* COM, 1* HDMI and 1* VGA; It supports 3G/4G/LTE, Wi-Fi/BT expansion, or industrial modules such as CAN-BUS/ProfiNet card via full-size Mini-PCIe slots.

TAICENN TBOX-2815 is a newest release high-performance fan-less industrial Box PC model, it adapts Intel Whiskey lake Core i3-8145U Dual core 2.1Ghz CPU, having advanced computer performance and low power consumption. TBOX-2815 storage can support 1 *M.2 PCIe 2242/2280 and 1* 2.5 inch SATA SSD or HDD; The design has a variety of communication interface, with 2* 2* RJ45 (Intel chips) ports, 2* USB 2.0, 4* USB 3.0 port, 6* COM (Optional with 2*S485/8*GPIO); The power input is DC 12V voltage, optional wide voltage DC 9~36V power range.

Model:TBOX-2815

● Rugged & compact, fanless designed box structure;

● On-board Intel Whiskey Lake 8th-gen. Core i3-8145U Dual-core processor;

● Single DDR4 memory, up to 16GB, 1* M.2 PCIe and 1* 2.5” SATA storage;

● DC 12V input, optional wide voltage DC 9~36V input;

● 2 GLAN, Dual wireless expansion 4G/5G, WIFI/BT support;

● 6 USB (4 USB3.0), 6 COM (optional GPIO), 2 HDMI;

● Industrial -20 ~ + 60℃ operating range, optional -40~+80 ℃.

Written at the end:

The rapid development of the food industry is inseparable from the help of the packaging industry. Food safety problems occur frequently, and consumers have put forward higher requirements for food packaging. The application of packaging robot in food packaging avoids the secondary pollution of food, improves the production efficiency and reduces the enterprise cost, meets the needs of the automation trend of the packaging industry, and also promotes the further improvement of the automation level of the packaging industry.