Blog

Why Industrial Panel PC are Essential for Modern Manufacturing Processes

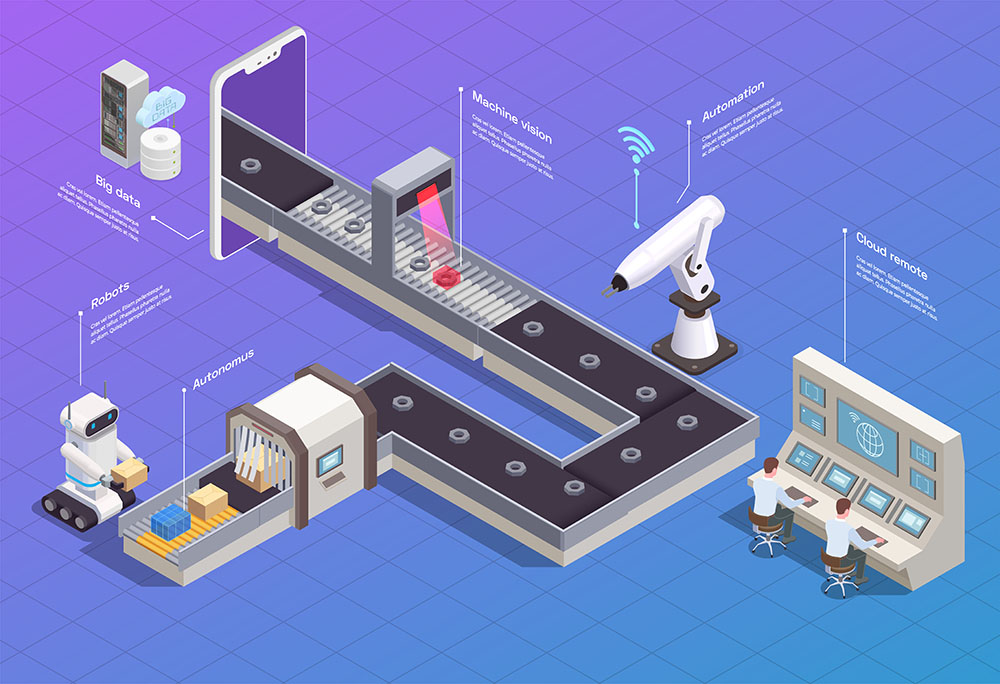

Are you ready to take your manufacturing processes to the next level? Look no further than industrial panel PC. These powerful and versatile devices are revolutionizing the way modern factories operate, with their advanced technology and rugged design. Whether you’re managing a small production line or overseeing a massive manufacturing facility, industrial panel PCs are essential tools that can streamline operations, increase productivity, and ensure optimal performance. In this blog post, we will explore what exactly an industrial panel PC is, how it differs from a regular PC, the benefits of using one in your manufacturing processes, and why they have become indispensable in today’s industry landscape. So grab a cup of coffee and let’s dive into the world of industrial panel PCs!

What is an industrial panel PC?

What exactly is an industrial panel PC? Well, think of it as a rugged and specialized computer system specifically designed for use in manufacturing environments. Unlike regular PCs that you may find in offices or homes, industrial panel PCs are built to withstand harsh conditions such as extreme temperatures, dust, vibrations, and even water. They are essentially all-in-one devices that combine the functionality of a computer with a high-resolution display screen.

An industrial panel PC is a specialized computer system designed for use in industrial environments, particularly in manufacturing settings. Here are some key features and considerations regarding industrial panel PCs:

Rugged and durable construction: Industrial panel PCs are built to withstand harsh conditions such as extreme temperatures, dust, vibrations, and water. They are often constructed with robust materials and components to ensure reliability and longevity in challenging industrial environments.

All-in-one design: These devices combine the functionality of a computer with a high-resolution display screen, typically in a single, compact unit. The integrated design saves space and simplifies installation.

Versatile connectivity

Industrial panel PCs are equipped with various input/output ports and interfaces to facilitate seamless integration with other equipment on the factory floor. They can connect to sensors, machinery controllers, data acquisition systems, and other devices commonly found in manufacturing processes.

Touchscreen interface

Many industrial panel PCs feature touchscreens for easy interaction and navigation. This eliminates the need for separate keyboards or mice and enables quick access to critical data and controls within manufacturing applications.

Processing power and storage capacity

Industrial panel PCs are equipped with powerful processors and ample storage capacity to handle complex tasks efficiently. They can run multiple applications simultaneously without compromising performance, making them suitable for real-time monitoring and running sophisticated control software.

Specialized software compatibility

Industrial panel PCs often run specialized software tailored for manufacturing purposes. This software may include applications for process control, data visualization, production monitoring, and more.

Mounting options

Industrial panel PCs can be mounted in various ways, such as wall-mounted, panel-mounted, or rack-mounted, depending on the specific requirements of the industrial environment.

Customization options

Some manufacturers offer customization options for industrial panel PCs, allowing users to tailor the specifications and features to their specific needs.

Industrial panel PCs are essential tools for optimizing production line efficiency and maintaining reliability in demanding manufacturing environments. They provide durable, versatile, and powerful computing solutions that can seamlessly integrate into existing factory operations.

An industrial panel PC is more than just a standard computer – it’s a durable workhorse designed for challenging manufacturing environments. Its rugged construction ensures reliability while its versatile features enable seamless integration into existing factory operations. So if you’re looking to optimize your production line efficiency while maintaining reliability in adverse conditions – an industrial panel PC should be at the top of your shopping list!

How does an industrial panel PC differ from a regular PC?

An industrial panel PC may look similar to a regular PC at first glance, but there are several key differences that set them apart. First and foremost, industrial panel PCs are built to withstand harsh environments. They are designed to be rugged and durable, able to function in extreme temperatures, dust-filled spaces, or high vibration areas.

Another important distinction is the touch screen feature of an industrial panel PC. Unlike a regular PC that relies solely on a keyboard and mouse for input, an industrial panel PC allows users to interact directly with the interface using their fingers or stylus. This makes it more user-friendly and efficient in manufacturing settings where quick responses are crucial.

Furthermore, industrial panel PCs often come with additional connectivity options such as serial ports or Ethernet ports that allow for seamless integration with other equipment or machinery on the factory floor. These connectivity options enable real-time data exchange and enhance productivity in modern manufacturing processes.

Additionally, unlike regular PCs which have limited expansion capabilities, industrial panel PCs can usually accommodate various add-ons like extra storage drives or PCI cards for specific industry requirements.

The robustness of an industrial panel PC coupled with its touch screen capabilities and enhanced connectivity make it ideal for use in demanding manufacturing environments. Whether it’s controlling production lines or monitoring critical processes, these specialized computers play a vital role in streamlining operations and ensuring efficiency throughout the modern manufacturing landscape.

The benefits of using an industrial panel PC

The benefits of using an industrial panel PC in modern manufacturing processes are numerous and significant. Industrial panel PCs are specifically designed to withstand the harsh conditions often encountered in manufacturing environments. With their rugged construction and robust components, these devices can handle extreme temperatures, vibrations, dust, and moisture that would quickly damage a regular PC.

Another advantage of industrial panel PCs is their versatility. These devices can be customized to meet specific requirements and integrate seamlessly with existing machinery or systems. They come with various connectivity options such as Ethernet ports, USB ports, serial ports, and even wireless capabilities. This allows for easy data transfer between different machines or monitoring devices.

Furthermore, industrial panel PCs offer enhanced visibility through their high-resolution displays and touch screen interfaces. This makes them ideal for applications where operators need to monitor real-time data or perform tasks quickly without relying on external peripherals like keyboards or mice.

In addition to durability and versatility, industrial panel PCs also prioritize safety. Many models come equipped with features such as fanless cooling systems to prevent the build-up of dust or debris that could pose fire hazards in certain environments.

These specialized computers often have long lifespans compared to regular PCs due to their durable design and reliable components. This results in lower maintenance costs over time for manufacturers.

The benefits of using an industrial panel PC make it an essential tool for modern manufacturing processes. Its durability ensures uninterrupted operations even in challenging conditions while its flexibility allows integration into various workflows. Enhanced visibility enables efficient monitoring of critical data points while prioritizing safety safeguards both personnel and equipment alike

How industrial panel PCs are used in manufacturing

Industrial panel PCs are a crucial component in modern manufacturing processes, providing a reliable and efficient solution for controlling and monitoring various operations on the shop floor. These specialized computers are designed to withstand the demanding conditions of industrial environments, making them an ideal choice for manufacturers.

One of the key uses of industrial panel PCs in manufacturing is process control. With their robust hardware and software capabilities, these devices can seamlessly integrate with other equipment on the production line to monitor and regulate critical parameters such as temperature, pressure, speed, and quality control. This ensures that manufacturing processes run smoothly and consistently.

In addition to process control, industrial panel PCs also play a vital role in data acquisition and analysis. By connecting sensors and input devices to these computers, manufacturers can collect real-time data from different stages of production. This data can then be analyzed using advanced software applications to identify patterns or anomalies that may impact productivity or product quality.

Furthermore, industrial panel PCs enable operators to have a centralized view of all operations within the facility through their high-resolution touchscreens. This allows for easy navigation between different screens or interfaces without having to switch between multiple devices.

Moreover,

Industrial panel PCs often come equipped with connectivity options such as Ethernet ports or Wi-Fi capabilities, enabling seamless integration with enterprise systems like ERP (Enterprise Resource Planning) or MES (Manufacturing Execution System). This facilitates streamlined communication across departments and enables real-time decision-making based on accurate information.

Another advantage of using industrial panel PCs is their rugged construction which makes them resistant to dust, moisture,and vibrations commonly found in harsh manufacturing environments.

These durable devices ensure uninterrupted operation even under extreme conditions,reducing downtime due to equipment failure significantly.

Why industrial panel PCs are essential for modern manufacturing processes

Whether it’s improving operational efficiency, enabling real-time monitoring and control, or facilitating seamless connectivity, industrial panel PCs are essential for modern manufacturing processes.

In summary, here are the key reasons why industrial panel PCs are essential for modern manufacturing processes:

- Durability: Industrial panel PCs are built to withstand harsh industrial environments, ensuring reliable operation even in challenging conditions.

- Specialized Features: These devices offer specialized features tailored for manufacturing, such as touchscreens for intuitive interaction, integration with other equipment, and real-time data visualization capabilities.

- Productivity Enhancement: Industrial panel PCs enable operators to monitor machine performance in real-time, identify issues quickly, and plan proactive maintenance, leading to improved productivity and reduced downtime.

- Customization: Manufacturers can customize industrial panel PCs to meet their specific production requirements, including screen sizes, processing power, and input/output configurations.

- Industry-Specific Software: Industrial panel PCs often come pre-installed with software applications designed for manufacturing processes, enhancing usability and functionality.

- Connectivity: Industrial panel PCs support seamless integration with existing networks and IIoT infrastructure, enabling data exchange, automation, and connectivity with other systems.

- Evolving Technology: As technology continues to advance, industrial panel PCs will evolve and adapt to meet the changing demands of modern factories, ensuring they remain essential tools in manufacturing processes.

Overall, industrial panel PCs provide the necessary durability, functionality, and connectivity to optimize production processes, enhance productivity, and meet the unique requirements of the modern manufacturing industry.

Conclusion

In conclusion, industrial panel PCs are indispensable tools in the modern manufacturing industry. Their rugged construction, specialized features, and adaptability make them well-suited for the demanding environments of industrial settings. They provide durability, reliability, and versatile functionality that regular PCs cannot match.

Industrial panel PCs enable manufacturers to streamline operations, improve productivity, and make better-informed decisions by accessing real-time data and monitoring key metrics. The high-resolution displays and touchscreen interfaces enhance visualization and facilitate precise control.

Moreover, industrial panel PCs are designed to withstand challenging conditions such as extreme temperatures, dust, moisture, and vibrations, ensuring uninterrupted operation in harsh industrial environments.

The integration of advanced connectivity options enables seamless communication between different machines and production units, supporting automation and synchronization of operations.

Overall, industrial panel PCs offer numerous benefits, including enhanced efficiency, cost savings, and improved decision-making through real-time data monitoring. Their rugged design and versatile functionality make them essential tools for manufacturers seeking to optimize their production processes.